Fixed vs. Mobile Palletizing: Which Is Right for Your Operation?

As palletizing becomes a higher priority for manufacturers facing labor shortages, safety concerns, and increasing production complexity, one key question comes up again and again:

Should palletizing automation be fixed — or mobile?

Both approaches can be effective, but the right choice depends heavily on your facility, your production model, and how much flexibility you need over time. Understanding the differences between fixed and mobile palletizing systems can help operations leaders make smarter, future-ready decisions.

At BTB Solutions, we’ve worked with both models across a wide range of manufacturing and logistics environments. What we’ve learned is simple: there is no universal answer — but there is a right fit for every operation.

What Is a Fixed Palletizing System?

Fixed palletizers are permanently installed automation systems, typically designed for a single production line or dedicated application.

They are often:

Anchored to the floor

Integrated tightly with conveyors and upstream equipment

Surrounded by permanent guarding or safety fencing

Engineered for high, consistent volumes

Where Fixed Palletizers Excel

Fixed palletizing systems make the most sense when:

Production runs are long and predictable

SKUs and pallet patterns rarely change

Floor space is available

Throughput requirements are consistently high

The palletizer will not need to move or be reconfigured

In these environments, fixed systems can deliver excellent performance and efficiency over the long term.

The Limitations of Fixed Palletizing

While powerful, fixed palletizers aren’t ideal for every facility.

Common challenges include:

Long installation timelines

Higher upfront integration effort

Limited flexibility once installed

Difficulty adapting to new products or layouts

Space constraints in older facilities

For manufacturers operating in brownfield environments or dealing with frequent changeovers, these limitations can become significant operational bottlenecks.

What Is Mobile Palletizing?

Mobile palletizing systems are designed to be compact, flexible, and easily redeployed across different areas of a facility.

Rather than being permanently tied to one line, mobile palletizers can:

Be moved between production lines

Fit into tight or constrained spaces

Operate independently or alongside existing equipment

Scale by adding additional units rather than redesigning layouts

This approach has gained traction as manufacturers look for automation that adapts to real-world production environments.

When Mobile Palletizing Makes More Sense

Mobile palletizing is often a better fit when:

Production lines change frequently

Multiple SKUs or pallet patterns are run

Space is limited

Automation needs to be deployed quickly

Capacity needs fluctuate seasonally

Teams want to start small and scale over time

Instead of committing to a single, permanent configuration, mobile systems allow operations leaders to respond faster to changing demands.

Brownfield vs. Greenfield: A Critical Factor

One of the biggest influences on palletizer selection is the type of facility.

Greenfield Facilities

Newly built plants often have:

Open layouts

Automation planned from day one

Space allocated for permanent systems

In these cases, fixed palletizing can be a natural fit.

Brownfield Facilities

Older facilities tend to have:

Tight aisles and crowded floor plans

Legacy conveyors and equipment

Limited room for guarding or expansion

Mobile palletizing systems are often better suited to these environments, as they can be deployed without major structural changes.

Flexibility Is Becoming a Strategic Advantage

Manufacturing today is defined by variability.

More SKUs, shorter runs, and shifting demand mean operations leaders are prioritizing systems that won’t lock them into one way of working for the next decade.

Mobile palletizing supports this shift by allowing teams to:

Reassign automation as priorities change

Scale palletizing capacity incrementally

Reduce risk when introducing automation

Avoid overbuilding for future scenarios

Rather than replacing fixed automation, mobile systems often complement it — filling gaps where flexibility is needed most.

Where BTB Solutions Fits In

At BTB Solutions, our experience spans both custom fixed automation and standardized mobile palletizing platforms. That perspective allows us to help manufacturers evaluate palletizing strategies based on real operational constraints — not just theoretical performance.

Some operations benefit from fixed systems. Others gain more value from mobile solutions. Many use a combination of both.

The key is understanding:

How stable your production really is

How much change your operation experiences

Where flexibility would deliver the most value

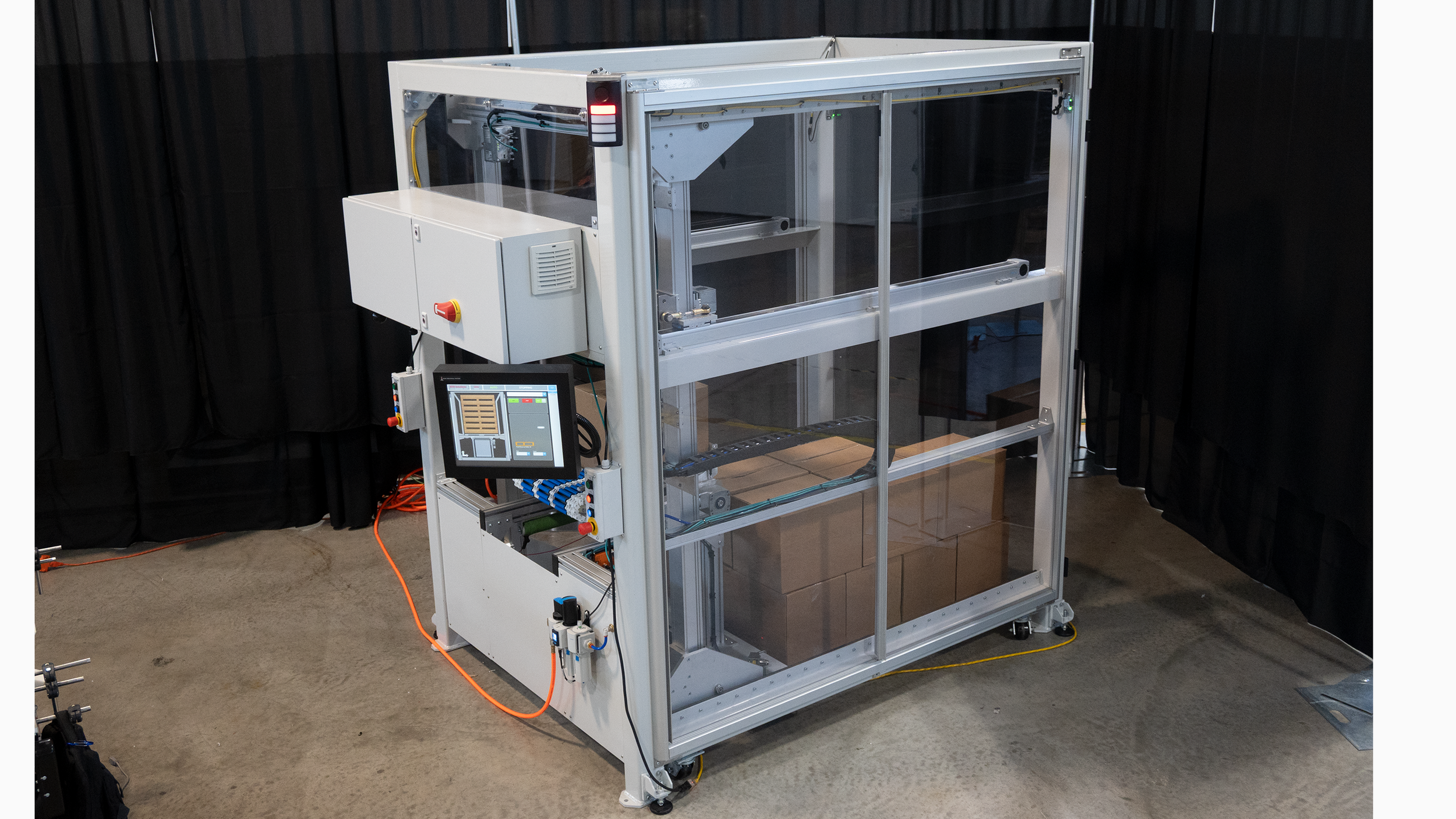

The UNO mobile Palletizing solutions

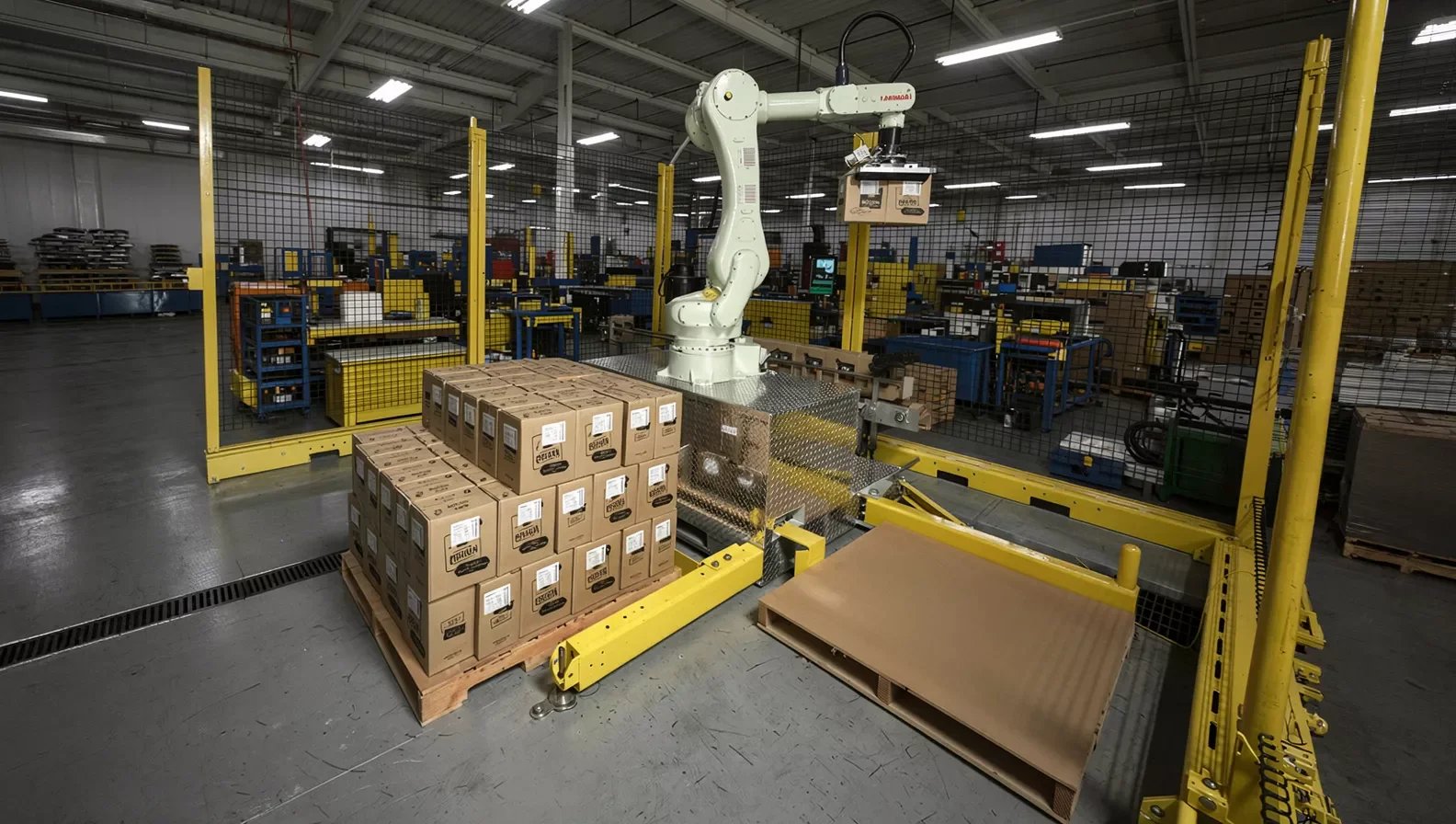

The REAPR fixed palletizing solution

Making the Right Choice

Choosing between fixed and mobile palletizing isn’t about which technology is “better.” It’s about which approach supports your operation today — and gives you room to adapt tomorrow.

For operations leaders evaluating palletizing automation, asking the right questions early can prevent costly rework, downtime, and frustration later.

As palletizing continues to evolve, flexibility, simplicity, and real-world fit are becoming just as important as raw throughput.