Custom Machines from BTB

Delivering Excellence Through Automation

Diverse Expertise

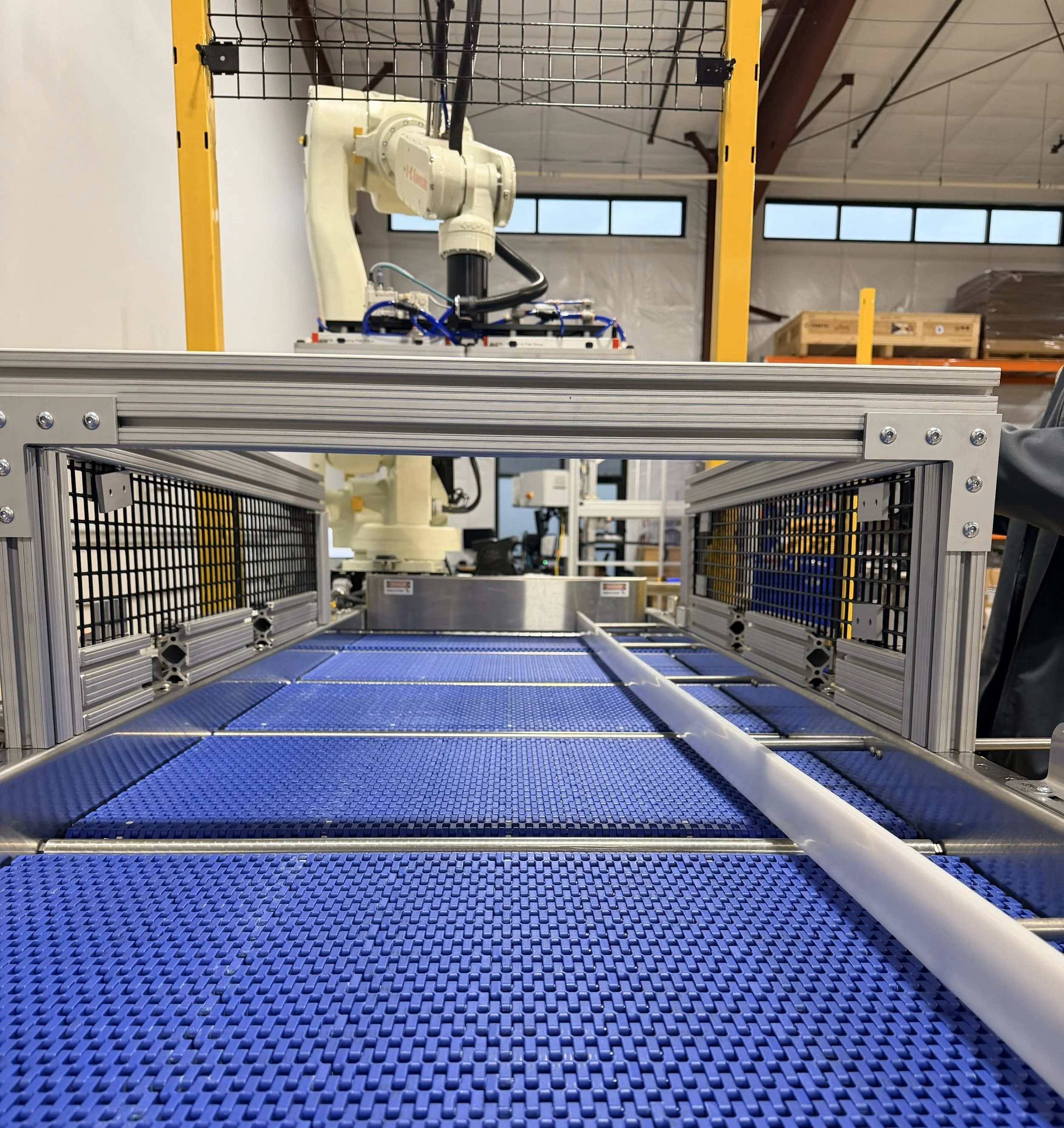

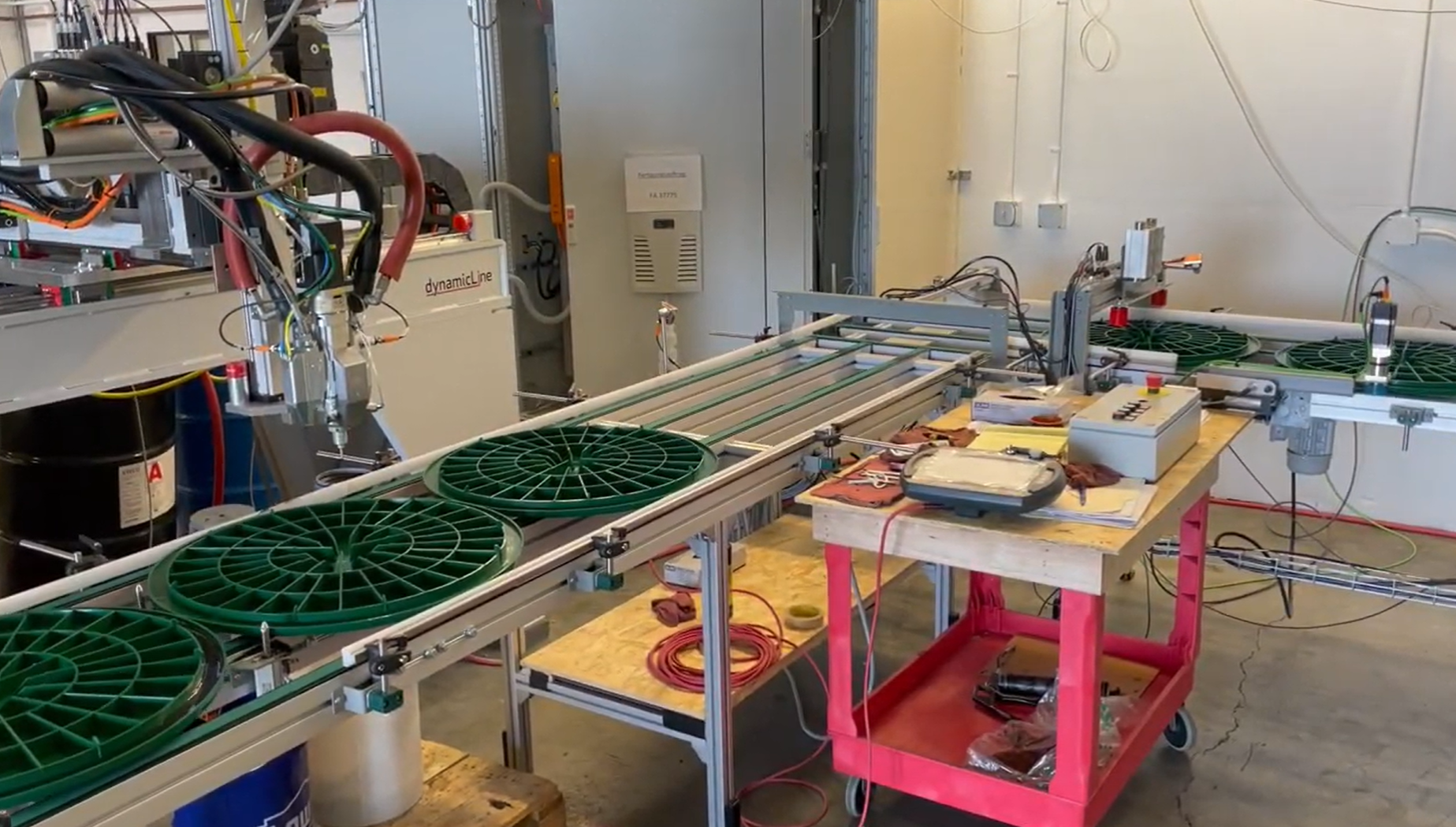

BTB Solutions brings hands-on automation experience across manufacturing, robotic welding, food processing, packaging, and industrial testing. Our team has designed and deployed custom systems in real production environments, giving us a clear understanding of uptime, safety, and throughput requirements.

That experience allows us to design automation that integrates cleanly, performs reliably, and scales as production demands change.

System Integration

BTB Solutions specializes in integrating proven control and robotic platforms into custom automation systems that work in real production environments. We have deep experience integrating Allen‑Bradley PLCs with robotic solutions from Kawasaki Robotics, FANUC, Universal Robots, ABB, and Epson Robots.

Whether building a system from the ground up or retrofitting existing equipment, we focus on clean integration across upstream and downstream processes—helping reduce downtime, improve efficiency, and support long-term reliability.

Delivering Excellence Through Automation

Proven Integration with Leading Automation Platforms

BTB Solutions integrates proven PLC and robotic platforms into production-ready automation systems, with a focus on uptime, safety, and long-term scalability.

Custom Automation & Equipment Retrofits

From new automation projects to retrofitting legacy equipment, we design systems that fit your operation and reduce capital risk while improving efficiency.

Real-World Engineering Experience

Our team brings hands-on experience across:

Manufacturing and packaging

Robotic welding systems

Food processing environments

Industrial testing applications

This real-world exposure allows us to anticipate production challenges and build automation that performs reliably under demanding conditions.

5 Reasons a BTB Custom Machine Is Right for You

1. Built Around Your Operation

BTB Solutions designs custom machines to fit your production flow, space constraints, and throughput goals. Instead of forcing your operation into a standard template, we build automation that integrates cleanly from day one.

2. Proven System Integration Experience

We bring deep experience integrating leading control and robotic platforms into reliable, production-ready systems. That means cleaner integration, fewer surprises, and smoother operation across your entire line.

3. Real-World Engineering Insight

Our team has hands-on experience across manufacturing, robotic welding, food processing, packaging, and industrial testing. That real-world exposure helps us anticipate challenges and design automation that performs under daily production demands.

4. Flexible Builds and Smart Retrofits

Whether you’re starting fresh or upgrading existing equipment, we design solutions that improve efficiency and extend asset life. The result is stronger performance without unnecessary capital replacement.

5. Designed to Scale Over Time

BTB custom machines are built with long-term growth in mind. Our systems are reliable, serviceable, and ready to expand—so your automation can grow as your operation does.